Everything About Oil Field Equipment and Pipeline Equipment: Key Insights and Essential Information

Oil field equipment and pipeline systems play a pivotal duty in the oil and gas industry. They are essential for the reliable extraction and transport of hydrocarbons. Trick components, such as drilling rigs and tank, directly impact operational success. Improvements in modern technology assurance to boost security and performance. Understanding these aspects is crucial for anybody associated with or interested in this complicated market, as it establishes the phase for deeper expedition of industry techniques.

Summary of Oil Field Equipment

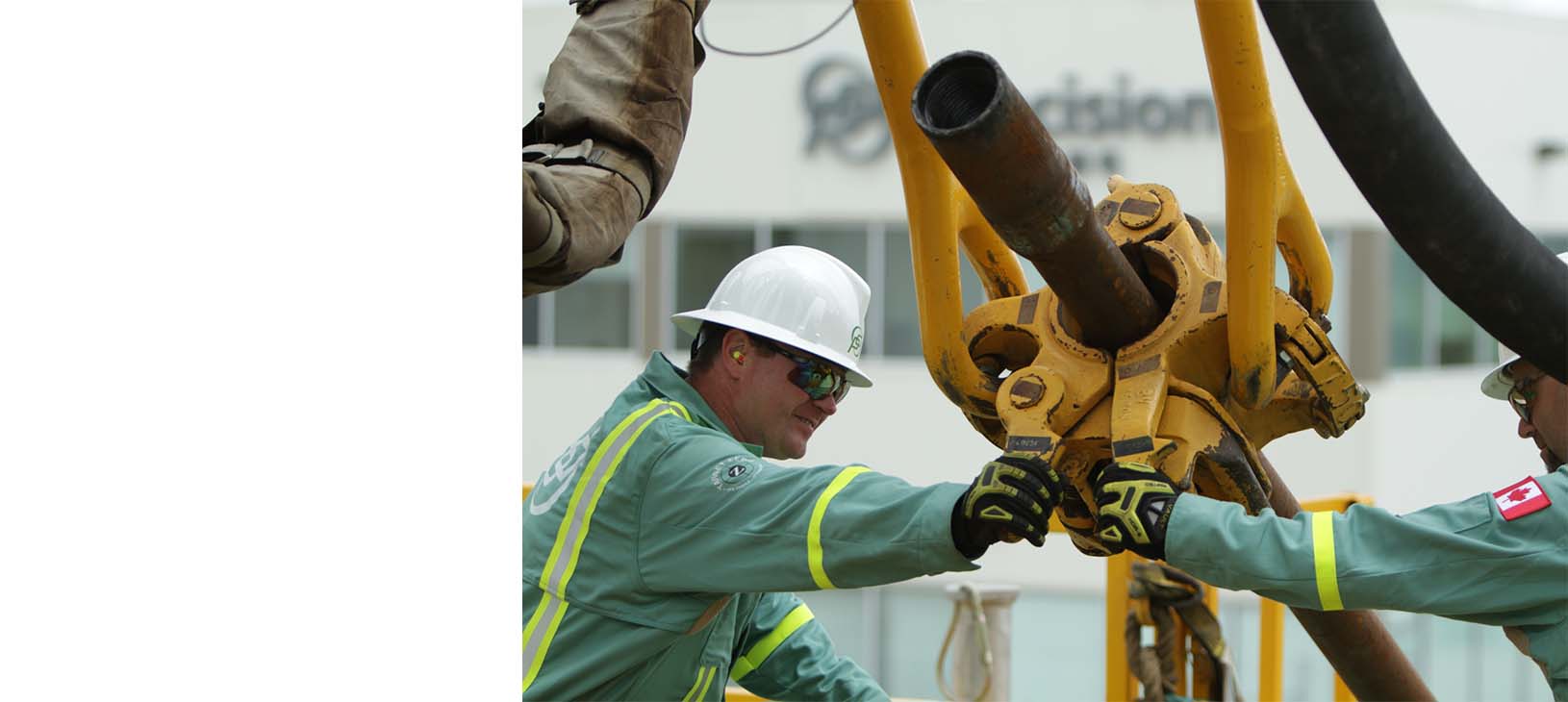

As the demand for oil continues to expand, comprehending the tools used in oil areas comes to be increasingly essential. Oil field equipment incorporates a large range of machinery and tools vital for exploration, extraction, and processing. Secret parts consist of drilling rigs, which are important for reaching oil reservoirs, and production equipment, such as separators and pumps, that help with the extraction process. Superior Oilfield Rentals oilfield. Furthermore, tank play a substantial duty in holding petroleum before transport. Safety equipment, consisting of blowout preventers and stress gauges, assures operational safety and security and efficiency. Each item of devices features cohesively to enhance production and maintain efficient operations. Experience with this equipment is necessary for specialists in the market to ensure successful procedures and adherence to security requirements

Sorts Of Drilling Rigs and Their Applications

Drilling rigs offer as the foundation of oil extraction procedures, with different kinds developed for particular geological problems and operational demands. One of the most usual types include rotary drilling rigs, which make use of a revolving drill bit to penetrate the earth, and cable device rigs, recognized for their percussion drilling approach. For offshore procedures, jack-up rigs and semi-submersible rigs supply security and support in aquatic environments. In addition, directional boring rigs make it possible for drivers to pierce at angles, getting to down payments that are not up and down available. Each gear type has distinct benefits, enhancing efficiency and safety and security based on the exploration environment. Choosing the suitable rig is important for taking full advantage of source extraction while lessening environmental influence and operational expenses.

Essential Pipeline Equipment and Their Functions

Pipeline infrastructure is vital for the transportation of oil and gas from extraction websites to processing centers and end-users. Various vital devices parts promote this procedure. Pipelines themselves work as the key conduits, made to withstand high pressure and corrosive materials. Pump terminals are essential for keeping circulation by enhancing stress along the pipeline. Shutoffs play an important role in controlling circulation and separating areas for maintenance. Furthermore, fittings and ports ensure safe and secure joints in between pipe sections. Checking systems, consisting of flow meters and pressure sensors, are essential for spotting leaks backhoe for sale by owner near me and maximizing flow rates. Pigging tools is used for maintenance and cleaning, securing pipeline honesty and efficiency. Together, these parts create the backbone of a trustworthy pipeline system.

Advancements and Technologies in Oil and Gas Equipment

Safety and Upkeep Practices in the Oil Sector

While the oil market has made significant strides in innovation and efficiency, the value of durable safety and upkeep practices can not be overemphasized. Reliable safety and security protocols are vital to shield employees and the environment, lessening the risk of mishaps and spills. Normal inspections and upkeep of equipment help determine possible problems prior to they intensify, making certain functional honesty. Educating programs for special info staff members are vital, emphasizing the significance of security awareness and emergency response treatments. Furthermore, adherence to market laws and requirements promotes a society of security. Applying innovative tracking technologies can better enhance upkeep practices, permitting real-time analyses of equipment conditions. Inevitably, prioritizing safety and security and upkeep is important to the sustainability and success of the oil market.

Regularly Asked Concerns

What Are the Environmental Influences of Oil Field Equipment?

The ecological effects of oil field equipment consist of environment damage, water contamination, and air contamination (Superior Oilfield Rentals oilfield). Additionally, equipment breakdown can cause spills, negatively impacting wild animals and environments, highlighting the need for stringent policies and tracking

Exactly How Is Oil Field Equipment Carried to Remote Locations?

Transferring oil field equipment to remote locations usually entails specialized cars, helicopters, or barges. Logistics companies coordinate routes, guaranteeing devices gets here securely and successfully, considering terrain and access to minimize delays and make the most of efficiency.

What Regulatory Specifications Govern Oil Field Equipment?

Regulative requirements controling oil field equipment mostly consist of security, environmental protection, and operational performance standards. Agencies such as OSHA and EPA apply these guidelines to ensure investigate this site risk-free practices and decrease ecological impact in oil extraction procedures.

What Abilities Are Required to Run Oil Field Equipment?

Just How Do Oil Rates Affect Equipment Need and Use?

Oil prices substantially influence devices need and usage. Higher rates commonly bring about raised exploration and manufacturing tasks, driving need for equipment. Conversely, reduced prices may lead to lowered procedures and decreased need for equipment.